All the latest news and views from Rinnai

Woodburners, or fires, are one of the most common types of space heating in New Zealand homes. One of the main reasons for their popularity is that we have an abundant supply of low-cost firewood. This low-cost source of energy can also be used to heat a home’s water via a wetback accessory and a specialised hot water cylinder.

How it works

The woodburner with wetback is connected to a storage water heating cylinder via a piped water connection. During the winter months, some of the heat produced by the woodburner is used to heat the water in the hot water cylinder. During the summer months when the wood burner isn’t used, the hot water cylinder operates as a normal cylinder would, heating the water via an electric element.

With a wetback system, the correct type of woodburner and cylinder must be chosen. The following is a summary of the types of hot water cylinders that are compatible with wetback systems.

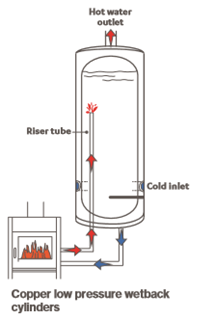

Low pressure copper wetback cylinder

|

Low pressure copper wetback cylinders are New Zealand’s traditional wetback hot water cylinders. As water is heated in the fire’s wetback, it rises into the low pressure copper wetback cylinder. Cold water then replaces the rising hot water in the circuit and woodburner. This cycle continues until the cylinder is heated. This type of system is an ‘open system’, meaning the water used in the home is running through the circuit and wetback system. |

|

The benefit of this type of system is that it’s robust and reliable as it has the least mechanical components (i.e. pumps and valves). The pressure created by the rising temperature is vented through an open pipe, usually above the roof of the home, instead of Temperature Pressure Relief valves (TPR valves).

The downside is that they are low-pressure systems so they supply much lower water pressure, which can mean a lower comfort level for shower use. Also, this type of system is not possible in all applications as it requires the cylinder to be installed close and in a higher position to the woodburner.

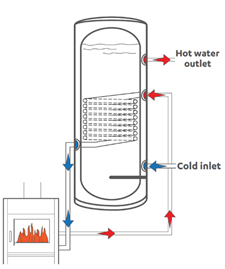

Mains Pressure Stainless Steel Thermosyphon Coil Cylinders

| This is the most common new install option and is becoming an increasingly popular choice of cylinder. This system works in a similar way to the low pressure copper wetback cylinder but uses a closed water circuit between the wetback fire and the cylinder. As water is heated, it rises through this circuit and through a coil in the cylinder. Heat is transferred via this coil into the useable water in the cylinder. |  |

The benefit of this type of cylinder is that while it has some mechanical components (valves) it doesn’t require a circulation pump. It also supplies mains pressure hot water which provides the best possible comfort level for showers. The downside is that TPR and cold water expansion valves are required. As water is routinely heated to high levels, these valves operate much more often than they would on a standard cylinder, so they must be replaced more often. This system also requires the cylinder to be installed close and in a higher position to the woodburner.

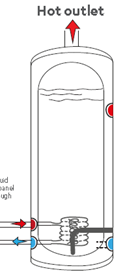

Mains Pressure Stainless Steel Standard Coil Cylinders

| This option is used in installations where the cylinder cannot be located in a close, raised position next to the woodburner. This system also uses a closed water circuit, but the heated water is pumped through the cylinder coil via a specialist high-temperature circulator pump. The heat is then transferred via the coil into the useable water inside the cylinder. |  |

While this type of cylinder allows more installation flexibility, it does need a circulation pump, which increases the maintenance requirements of the system. The benefit of this system is that the heat input into the cylinder can be controlled via the pump, which builds in an element of temperature control to the system.

Cylinder size

Generally, the flow of heat into the cylinder isn’t controlled and the water inside the cylinder will continue to heat while the fire is burning. This means temperatures inside the cylinder will be much hotter than in a standard cylinder. At these high temperatures, steam and hot water are expelled and replaced by colder water.

To get the most benefit from the wetback system, it’s best to be able to store more water to capture this excess heat. Where possible, it’s best to install a wetback cylinder with a higher volume capacity than a standard domestic cylinder. This is to allow the cylinder to hold more heat and minimises the hot water being expelled. While a 180L is the most common standard cylinder in the home, installations of wetbacks tend to be 250L to 300L where space allows.

These large cylinders are also available with the electric elements in the upper part of the cylinder. During the summer months when the woodburner isn’t burning, only the upper part of the cylinder is heated, supplying a similar volume of hot water as a standard cylinder. The user isn’t paying for the electricity to heat water they wouldn’t normally use.

Low pressure copper wetbacks are usually installed as a replacement for an older, failed cylinder. In these replacement installations, space can be limited so smaller cylinders are often used.